How to Stop Electrolysis on Aluminum | Prevention Techniques 2025

The best way to stop electrolysis on aluminum is to remove the oxygen from the metal. This can be done by anodizing the metal. Anodizing creates a thin layer of oxide on the surface of the metal, which prevents further corrosion.

- Rinse the aluminum with water to remove any dirt or debris

- Fill a container with a vinegar and water solution, and submerge the aluminum in it

- Let the aluminum soak in the vinegar solution for several hours, or overnight if possible

- Remove the aluminum from the vinegar solution and rinse it off with water

- Dry the aluminum thoroughly with a clean cloth or towel before storing or using it again

Boat Electrolysis Test

Boat electrolysis test is a process of measuring the amount of current produced when an electric potential is applied between two electrodes placed in an electrolyte. The test is used to determine the rate at which corrosion is occurring on metal surfaces that are exposed to salt water.

It’s important to perform this test regularly, as boat electrolysis can lead to serious problems like structural damage and even sinking if left unchecked.

The good news is that it’s relatively easy to do, and only requires a few simple supplies that you probably already have on hand.

Here’s what you’ll need for the test:

– A voltmeter (to measure the voltage drop across the electrodes)

– Two alligator clips (to connect the voltmeter leads to the electrodes)

– A small container of salt water (for the electrolyte)

– Two pieces of scrap metal or coins (for the electrodes)

– A 6V battery (to provide the electric potential)

simply place one electrode in each hand, clip one lead from the voltmeter to each electrode, then immerse both electrodes in the salt water. If everything is working properly, you should see a reading on the voltmeter.

The higher the reading,the greater the level of corrosion taking place.

How to Fix Electrolysis in Aluminium Boats

If your aluminium boat is suffering from electrolysis, there are a few things you can do to fix the problem. First, check the hull for any areas that may be corroding. If you find any, sand them down and treat them with a corrosion-resistant coating.

Next, check the anodes on your boat. If they’re corroded, replace them with new ones. Finally, make sure that your boat’s electrical system is in good working order.

If it isn’t, have it repaired or replaced by a qualified technician.

Boat Electrolysis Protection System

If you own a boat, you know that electrolysis can be a big problem. This is when water seeps into the metal of your boat and causes it to corrode. This can lead to big problems down the road, so it’s important to protect your investment with a boat electrolysis protection system.

There are a few different types of boat electrolysis protection systems on the market, but they all work to do one thing: prevent water from coming into contact with the metal of your boat. Some systems use a chemical barrier that coats the metal and prevents water from getting through. Others use physical barriers like gaskets or seals to keep water out.

No matter which type of system you choose, make sure that you have it installed by a professional. This will ensure that it works properly and lasts for as long as possible. With a good boat electrolysis protection system in place, you can rest easy knowing that your boat is safe from this damaging condition.

Electrolysis Boat Damage

If you’ve ever taken your boat out for a spin, only to find that it’s not working as well as it used to, you may be a victim of electrolysis. This phenomenon occurs when electrical current from an outside source interacts with the metal in your boat’s hull, causing it to corrode. Over time, this corrosion can cause serious damage to your boat and may even render it unusable.

The best way to protect your boat from electrolysis is to be proactive and take steps to prevent it from happening in the first place. One way to do this is by using anodes, which are pieces of metal that are placed in the water around your boat and act as a sacrificial material. When electrical current comes into contact with the anode, it will interact with the metal first, instead of your boat’s hull.

Anodes need to be replaced regularly, so be sure to check on them periodically and replace them as needed.

Another way to prevent electrolysis is by ensuring that all electrical connections on your boat are secure and free of corrosion. Anytime you’re working on electrical systems on your boat, take extra care to make sure that all connections are tight and free of rust or other corrosion.

If you notice any signs of corrosion on electrical components, have them replaced immediately before they cause further damage.

If you suspect that your boat has already been damaged by electrolysis, there are some things you can do to try and repair the damage. First, sand down any areas of the hull where there is visible corrosion or pitting.

Next, apply a sealant or primer designed for use on boats – this will help protect the hull from further damage.

What Causes Electrolysis on a Boat

If you’ve ever taken your boat out for a day on the water, only to find it covered in unsightly electrolysis stains when you get home, you’re not alone. Electrolysis is a common problem for boat owners, but fortunately there are ways to prevent it. So what causes electrolysis on a boat?

Simply put, electrolysis is the process by which metal ions are transferred from one object to another through an electrically charged solution. When two dissimilar metals (such as aluminum and stainless steel) come into contact with each other in an electrically conductive environment (like salt water), electrons flow from the more negative metal to the more positive metal. This creates an electrochemical reaction that can corrode or damage both metals.

There are several factors that can contribute to this process, including:

-The type of metals involved: Some metals are more susceptible to electrolysis than others. Aluminum boats are particularly prone to this problem since aluminum is a relatively “active” metal that readily gives up its electrons.

-The level of salinity in the water: The higher the concentration of salt in the water, the greater the risk of electrolysis. This is why boats kept in saltwater are more likely to experience this issue than those kept in freshwater.

-The presence of electrical current: Any time there’s an electrical current present (such as when charging a boat battery), there’s a risk of electrolysis occurring.

-The length of time two metals are in contact with each other: The longer two dissimilar metals are touching each other, the greater the chance of corrosion happening.

Fortunately, there are steps you can take to prevent or minimize electrolytic corrosion on your boat. These include using sacrificial anodes made from zinc or magnesium (which will corrode before your boat does), coating vulnerable areas with marine paint or epoxy resin, and making sure all electrical connections are clean and tight fitting.

Credit: www.jetdock.com

How Do You Stop Electrolysis?

There are many ways to stop electrolysis, but the most common and effective way is to use a corrosion inhibitor. A corrosion inhibitor is a substance that prevents or slows down the chemical reaction between metals and water. This can be done by using anodic inhibitors, cathodic inhibitors, or both.

Anodic inhibitors work by preventing the metal from oxidizing, while cathodic inhibitors work by prevent the water from reducing the metal.

How Do You Stop Electrolysis on Aluminium Boat?

If you’re unlucky enough to have electrolysis on your aluminium boat, there are a few things you can do to stop it. The first is to make sure that the anode and cathode are separated. You can do this by using different metals for the anode and cathode, or by using a dielectric material between them.

The second is to make sure that the anode has a larger surface area than the cathode. This will help to prevent localised corrosion at the anode. Finally, you can use a sacrificial anode made of zinc or magnesium.

This will corrode in preference to the aluminium, providing some protection for your boat.

Does Zinc Stop Electrolysis?

No, zinc does not stop electrolysis. Electrolysis is the process of using electricity to break down a substance into its component parts. Zinc is a metal that is often used as an electrode in electrolysis because it is resistant to corrosion and has a low reactivity.

How Do You Prevent Galvanic Corrosion in an Aluminum Boat?

Galvanic corrosion is a process that occurs when two dissimilar metals are in contact with each other in an electrolyte. When this happens, one metal will corrode at a faster rate than the other. This can be a major problem for aluminum boats, as aluminum is much more susceptible to galvanic corrosion than other metals.

There are a few things you can do to prevent this from happening:

1) Use a sacrificial anode: This is a piece of metal that is placed in the water near your boat that will corrode instead of your boat. You will need to check on the anode regularly and replace it as necessary.

2) Coat your boat with zinc: Zinc has a higher electrochemical potential than aluminum, so it will corrode first if there is any galvanic corrosion occurring. This will protect your boat from the corrosive effects of salt water and keep it looking like new for longer.

3) Use fresh water: If you can, try to keep your boat in fresh water as much as possible.

Salt water is more conductive and therefore promotes galvanic corrosion more than fresh water does.

4) Avoid using dissimilar metals: If possible, don’t use dissimilar metals (such as aluminum and stainless steel) on your boat. If you must use them, make sure they are well insulated from each other so that there is no direct contact between them.

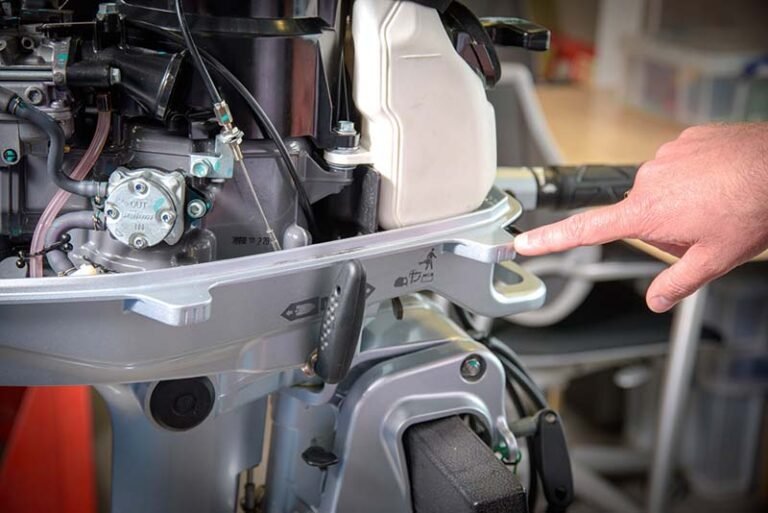

Electrolysis (Stray Current) Damage and Hull Prep – E09

Conclusion

The best way to stop electrolysis on aluminum is to use a corrosion-resistant paint or anodized coating. This will protect the metal from oxygen and water, which can cause it to corrode.