How to Speed Up 5200 Cure Time | Accelerating 5200 Adhesive Cure Time 2025

If you need your 5200 to cure faster, there are a few things you can do. First, make sure you’re using the right amount of catalyst – too much or too little will extend the cure time. Second, apply heat to the area – either with a heat lamp or by increasing the ambient temperature.

Finally, if possible, increase air circulation around the area to help speed up the curing process.

- The 5200 cure time can be speed up by taking the following steps: 1

- Preheat the area to be bonded with a heat gun

- This will help to evaporate any moisture that may be present and improve the adhesion of the 5200

- Apply a generous amount of 5200 to one surface, spreading it evenly with a putty knife or your finger

- Press the two surfaces together firmly, then wipe away any excess adhesive with a rag or paper towel

- Use a hair dryer or heat gun to apply even more heat to the area if needed

- The warmer the temperature, the faster the 5200 will set and cure

3M 5200 Cure Time

3M 5200 is a marine-grade sealant that is commonly used in boatbuilding and repairs. It has a very strong bond and can be used on a variety of materials, including wood, fiberglass, and metals. 3M 5200 has a cure time of 24-48 hours, so it is important to plan your project accordingly.

Once cured, 3M 5200 is very durable and weather resistant.

3M 5200 Fast Cure Vs Regular

If you’re in the market for a marine sealant, you’ve probably come across 3M 5200 Fast Cure. But what is it, and how does it differ from regular 3M 5200? Here’s a quick rundown of the key differences between these two products:

3M 5200 Fast Cure is a one-part polyurethane that cures quickly at room temperature. It’s designed for use in areas where a fast cure time is essential, such as on boat hulls or deck fittings that need to be back in service quickly. Regular 3M 5200, on the other hand, has a slower cure time of 24-48 hours.

3M 5200 Fast Cure also has slightly different physical properties than regular 3M 5200. It’s more flexible and resistant to impact, making it ideal for use in areas subject to stress or vibration. And because it cures quickly, it can be sanded and painted sooner than regular 3M 5200.

One downside of 3M 5200 Fast Cure is that it’s not as strong as regular 3M 5200; while both products have excellent adhesion and weather resistance, regular 3M 5200 forms a stronger bond. So if strength is your top priority, stick with the original formula.

otherwise go with whichever product better suits your needs in terms of cure time and flexibility.

3M 5200 Cure Temperature

When it comes to adhesives, there are different factors that can affect the curing process. One of those factors is temperature. In general, lower temperatures will result in a longer cure time while higher temperatures will shorten the cure time.

However, it’s important to note that too high of a temperature can actually prevent the adhesive from curing properly. With that in mind, let’s take a look at the ideal cure temperature for 3M 5200 adhesive.

3M 5200 is an extremely versatile adhesive that can be used for a variety of applications.

It has excellent bonding strength and can even be used on wet surfaces. When it comes to cure temperature, 3M 5200 should be cured at room temperature (70°F/21°C). Curing at this temperature will result in optimal bonding strength and flexibility.

Of course, there may be times when you need to speed up the curing process or bond two pieces together in colder temperatures. In those cases, you can use a heat gun or hair dryer to raise the surface temperature of the materials being bonded. Just be sure not to exceed 120°F/49°C as this could cause the adhesive to lose its effectiveness.

3M 5200 Not Curing

If you are having problems with 3M 5200 not curing, there are a few things that you can do to try and fix the issue. First, make sure that you are using the correct amount of catalyst. Too much or too little can prevent the adhesive from curing properly.

Second, check the temperature of your work area – if it’s too cold, the 3M 5200 will take longer to cure. Finally, make sure that you are giving the adhesive enough time to cure before putting any weight on it – at least 24 hours is ideal.

Can You Apply 5200 to a Wet Surface

Applying 5200 to a wet surface is not recommended and may result in poor adhesion. If you must apply 5200 to a wet surface, be sure to thoroughly clean and dry the area first. For best results, apply 5200 when both the temperature and humidity are low.

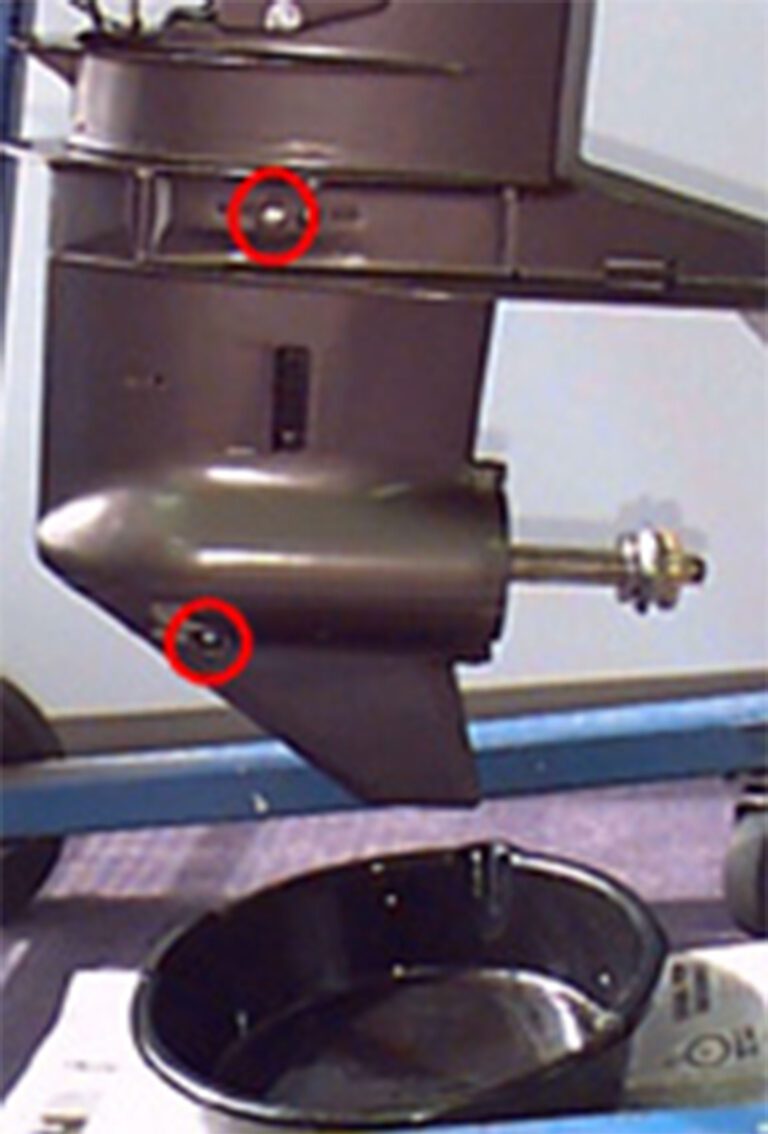

Credit: www.3m.com

How Long Does It Take to Cure 5200 Fast?

5200 is a marine sealant that is used to waterproof boats and other vehicles. It takes about 24 hours to cure fully.

How Long Does 3M 5200 Slow Cure?

3M 5200 is a marine-grade adhesive/sealant that is effective in bonding and sealing many types of surfaces. It has a slow cure time, which means that it takes longer to set and cure than other similar products. Depending on the temperature and humidity, it can take anywhere from 24 to 72 hours for 3M 5200 to fully cure.

Does 3M 5200 Dry Hard?

3M 5200 is a marine-grade sealant that dries hard. It is designed for use on boats and other watercraft, as well as around pools and other wet areas. The sealant forms a waterproof barrier that prevents moisture from seeping through cracks and gaps.

3M 5200 can be applied to both wet and dry surfaces, and it cures in 24 hours.

Will 3M 5200 Cure Underwater?

If you’re in need of a sealant that can withstand being submerged in water, then 3M 5200 is not the right product for you. This sealant is designed for above-water use only and will not cure properly if applied underwater. For applications that require a waterproof seal, we recommend using our 3M 6000 series sealants.

3M 5200 Fast Cure Product Demo

Conclusion

While it may seem like a daunting task to speed up the 5200 cure time, with a little effort and some planning it is definitely possible. By following the tips and tricks outlined in this blog post, you’ll be on your way to reducing your 5200 cure time in no time!