Why Won’T My Boat Motor Trim Up | Trim Issue Troubleshooting 2025

There are a few reasons why your boat motor trim may not be working. One reason could be that the hydraulic fluid level is low. Another reason could be that there is something blocking the hydraulic pump from working properly.

If you have checked these two things and the problem still persists, it is likely that there is a problem with the trim tabs themselves. The most likely scenario is that the trim tab cylinders need to be replaced.

If you’ve ever been out on a boat and tried to adjust the motor trim, only to find that it won’t move, you’re not alone. Many boat owners have experienced this frustrating problem at one time or another. There are a few possible reasons why your boat motor trim won’t adjust.

One possibility is that the cable that runs from the trim switch to the motor is damaged or frayed. If this is the case, you’ll need to replace the cable. Another possibility is that there is something blocking the movement of the trim tab itself.

This could be debris caught in between the tab and the hull or a buildup of algae or barnacles on the tab itself. If you suspect this is the problem, you’ll need to clean off the trim tab so that it can move freely again.

Whatever the reason for your boat motor trim problems, it’s important to get them fixed as soon as possible.

Not being able to adjust your motor trim can make driving your boat difficult and even dangerous. So if you’re having trouble getting your boat’s motor trim to work properly, don’t hesitate to take it into a qualified marine technician for diagnosis and repair.

Boat Motor Won’T Go Up Or down

Boat motors are designed to move the boat through the water using a propeller. The motor is attached to the back of the boat and usually has two large handles that control the up and down movement of the motor. If your boat motor won’t go up or down, there are a few things you can check to troubleshoot the issue.

First, check to make sure that there is gas in the tank. If there is no gas, then the engine will not be able to run and power the propeller. Next, check all of the connections between the battery and the engine.

Make sure that all of the wires are securely connected and that there is no corrosion on any of the terminals.

If those two things check out, then it’s likely that there is an issue with either the impeller or prop shaft. The impeller is what actually moves water throught he system and if it’s damaged, then it won’t be able to do its job properly.

The prop shaft connects teh impeller to teh engine and if it’s bent or damaged in any way, then it can prevent proper communication between those two parts.

Inspect both of those components for damage and if you find any, replace them with new ones. With any luck, that will fix your problem!

Power Trim Slowly Goes down

As your boat moves through the water, the propeller blades create lift and thrust. But as they do, they also create drag. Power trim is a system that helps to minimize this drag by automatically adjusting the angle of the propeller blades.

Over time, power trim can slowly start to lose its effectiveness. This is most likely due to a build-up of algae or other debris on the trim tabs or in the power trim mechanism itself. If you notice that your boat’s power trim is not working as well as it used to, there are a few things you can do to try and fix the problem.

First, check the trim tabs themselves for any dirt or debris. If they’re clean, then take a look at the power trim mechanism itself. It may be helpful to consult your owner’s manual for specific instructions on how to maintain and clean this system.

If neither of these solutions seems to be working, then it’s possible that more serious repairs are needed. In this case, it’s best to consult with a qualified marine mechanic who can diagnose and fix the problem correctly.

Power Trim Goes down But Not Up

If you have a power trim that goes down but not up, there are a few things that could be causing the problem. The most common cause is a bent or broken drive shaft. If the drive shaft is bent, it will need to be replaced.

Another possibility is that the drive pulley is seized and needs to be replaced.

Outboard Trim Bleeding down

If you’ve ever had your outboard motor trimmed down and then back up again, you know that it can be a real pain to get the trim working properly. The good news is that there’s a way to bleed the trim lines and get everything working like new again. Here’s what you need to do:

1. Find the bleed screws on your outboard motor. These are usually located near the top of the engine, on either side of the powerhead.

2. Using a flathead screwdriver, loosen each of the bleed screws about a half-turn.

3. Have someone start the engine and let it run for a few minutes while you check for leaks at the bleed screws. If there are any leaks, tighten the screws until they stop.

4. Once the engine has been running for awhile, have your helper shut it off and then carefully remove the pressure relief cap from the powerhead (this is usually located near the top of the engine).

Be careful not to touch anything hot!

5. With the pressure relieved, finish loosening each of the bleed screws until fluid starts coming out in a steady stream (you may need to help gravity along by tilting the outboard motor so that fluid runs towards the bleed screw). Keep bleeding until all air bubbles have been flushed from system and only clean fluid is coming out of each line.

Tilt And Trim Motor Runs But Won’T Move

If your tilt and trim motor runs but won’t move, there are a few possible causes. First, check to make sure that the shear pin is intact. If the shear pin has broken, the motor will need to be replaced.

Another possibility is that the drive belt has come off or is damaged. The drive belt connects the motor to the pump, so if it’s not functioning properly, the motor won’t be able to move the oil. Finally, there could be an issue with the hydraulic fluid.

If there isn’t enough fluid in the system, or if it’s old and needs to be replaced, that could also cause the problem. No matter what the cause of your tilt and trim issues may be, it’s always best to consult a professional for help before attempting any repairs yourself.

Credit: www.youtube.com

What Controls the Trim on a Boat?

There are a few things that control the trim on a boat. The first is the weight distribution. If the weight is not evenly distributed, it will cause the boat to lean to one side or the other.

This can be remedied by either moving weight around or adding weight to the opposite side.

The second thing that controls trim is the wind. If there is a strong wind blowing from one direction, it will push the boat in that direction and cause it to lean.

The only way to counteract this is by using the rudder to steer into the wind and keep the boat balanced.

Finally, waves can also affect trim. As they hit the hull of the boat, they can cause it to rock back and forth or even tip over if they are big enough.

To avoid this, you need to make sure that you have enough ballast (weight) in the boat so that it stays stable in rough waters.

How Do You Manually Lift a Boat Trim?

Assuming you are asking how to manually adjust a boat’s trim tabs:

Most boats have hydraulic or electric trim tabs. However, it is possible to manually adjust trim tabs on some boats.

To do this, you will need to locate the manual adjustment knob for the trim tab. This is usually located near the trim tab itself. Once you have found the knob, turn it in the direction that you want the trim tab to move.

For example, if you want the bow of the boat to rise out of the water, you would turn the knob towards the stern of the boat.

How Do I Raise the Trim on My Boat?

If you’re looking to raise the trim on your boat, there are a few things you’ll need to do. First, check your owner’s manual to see if there are any specific instructions from the manufacturer. Next, identify the adjustment screws or bolts on the outboard motor.

These are usually located near the top of the motor. Once you’ve found them, use a wrench or screwdriver to turn them clockwise to raise the trim. If you’re still having trouble raising the trim, consult a professional for help.

Why is My Boat Motor Not Getting Full Power?

If your boat motor isn’t getting full power, there are a few potential causes. The most common cause is an issue with the fuel system, which can be anything from a dirty fuel filter to a clogged fuel line. Another possibility is an issue with the ignition system, such as a weak spark or faulty spark plugs.

If neither of these seem to be the problem, it’s possible that the engine itself is not getting enough air or cooling water. Lastly, make sure that all of the boat’s batteries are in good condition and properly connected; if one battery is failing, it could affect the performance of the entire system. If you’re still having trouble pinpointing the problem, it’s best to consult a professional mechanic or boat dealer for assistance.

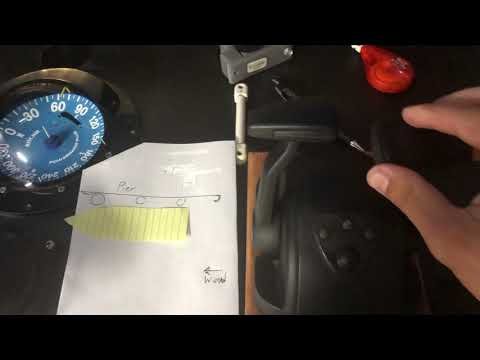

Simple Fix for a Boat Power Trim Not going Up or Down (Boat Trim Not Working) 2 Stroke

Conclusion

After reading this blog post, it is clear that there are several potential reasons why a boat motor trim may not work properly. In some cases, the problem may be as simple as a loose wire or dirty connection. However, it is also possible that the trim pump itself is damaged or malfunctioning.

If the problem cannot be easily resolved, it may be necessary to take the boat to a qualified technician for further diagnosis and repairs.