How to Manually Raise an Inboard Outboard Motor | Lifting Guide 2025

The inboard outboard motor, or I/O, is a type of boat propulsion system that combines features of both inboard and outboard motors. I/Os are popular because they offer the maneuverability of an outboard and the power and efficiency of an inboard. To manually raise an I/O motor, first locate the manual release valve.

This is usually located near the base of the motor. Once you have found the release valve, turn it counterclockwise to release any pressure that may be holding the motor down. Next, use your hands to raise the motor until it is in the fully upright position.

Be sure to support the motor with your hands as you do this to avoid damaging it. Finally, close the manual release valve by turning it clockwise.

- Park the boat on a flat surface and make sure it is secure

- Remove the drain plug from the lower unit and allow any water to drain out

- Place a block of wood under the motor to support it while you are working

- Locate the manual release valve on the engine and turn it counterclockwise to release any pressure that may be in the system

- Slowly raise the motor using the hydraulic lift until it is in the desired position

How to Manually Lower an Inboard Outboard Motor

Assuming you have an inboard outboard motor and not just an outboard motor, there are a few things you need to do in order to lower it manually. This process is known as de-rigging the engine.

First, you need to disconnect the fuel line from the engine.

Next, disconnect the electrical cables from the engine. Finally, remove the bolts that hold the engine to the transom or swim platform.

With all of those steps complete, you should be able to lower your inboard outboard motor by hand.

Be sure to place it on a soft surface so as not to damage the engine.

How to Raise a Mercury Outboard Motor Manually

If you’re a boater, you know that sometimes your Mercury outboard motor can become stuck in the “down” position. If this happens, don’t panic! There is a way to raise the motor manually so you can get back to enjoying your time on the water.

Here’s what you’ll need:

– A long rope or strap

– A partner (to help steady the boat while you work)

– A Phillips head screwdriver (for loosening/tightening the engine coupler)

First, tie one end of the rope or strap around the base of the outboard motor. Make sure it’s snug, but not too tight – you don’t want to damage the motor.

Next, have your partner hold onto the other end of the rope or strap while you gently pull on it. The goal is to slowly and evenly raise the outboard until it’s in the upright position. Once it’s up, use your screwdriver to loosen/tighten the engine coupling so it doesn’t fall back down.

And that’s it! You’ve successfully raised your Mercury outboard manually.

Manually Raise Mercruiser Outdrive

If you have a Mercruiser outdrive, you may need to manually raise it at some point. This can be done by disconnecting the drive from the boat and then raising it with a hand crank or by using a winch. Once the drive is disconnected, you will need to support it with something so that it doesn’t fall back down.

A couple of strong ropes should do the trick. Once you have the drive raised, you can then proceed to work on whatever needs to be fixed. Keep in mind that this is not a difficult process, but it is one that requires some care and attention.

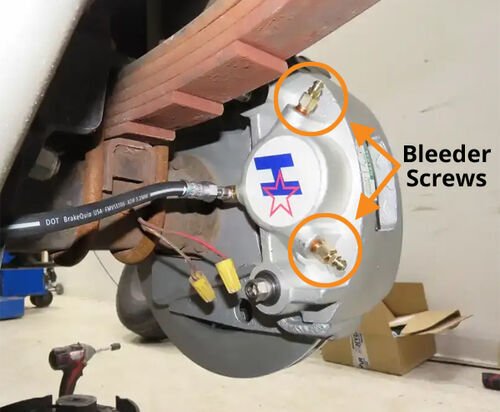

Mercury Power Trim Manual Release Valve Location

The Mercury power trim manual release valve is located on the side of the engine near the transom. It is a small, round, black knob that is recessed into the side of the engine. To use it, simply unscrew the knob counterclockwise and pull it out.

Doing this will relieve pressure from the hydraulic system and allow you to manually move the power trim up or down.

How to Manually Raise a Yamaha Outboard Motor

If you own a Yamaha outboard motor, you may eventually need to manually raise the motor. This can be done for a variety of reasons, such as when you’re changing the oil or if the engine has been flooded. Whatever the reason, it’s not a difficult task and only takes a few minutes to complete.

To start, lay down a tarp or something similar to catch any oil or water that may drip from the engine. Next, locate the manual release valve on the side of the engine. It will be located near where the fuel line attaches to the motor.

Once you’ve found it, turn it counterclockwise until it stops.

Now it’s time to physically raise the engine out of the water. There are two ways to do this – by hand or with a lift – but either way works fine.

If raising by hand, simply grab hold of the engine and lift straight up. If using a lift, lower it down so that the straps are around where they need to be (usually just below wherethe cylinder head meets the block) and then slowly raise it until clear ofthe water.

Once raised, there’s one final step before starting work onthe engine itself and that’s placing supports underneath it so thatit doesn’t fall back into position and potentially cause damage orgive you an injury in the process.

With these in place, you can nowproceed with whatever maintenance task you needed to do in themotor in order begin with!

Credit: www.texassaltwaterfishingmagazine.com

How Do You Manually Raise an Inboard Boat Motor?

Assuming you need to raise your inboard boat motor for maintenance or repairs, there are a few ways to go about it. One is to use a jack and place it under the engine, then crank the jack until the engine is raised to the desired height. Another way is to use straps or rigging to support the engine from above, then lift it with a crane or come-along.

Whichever method you choose, be sure to take extra care and use caution, as raising an inboard boat motor is no small feat!

Can You Crank an Inboard Motor Out of the Water?

If your inboard motor is giving you trouble and you need to take it out of the water for repairs, don’t despair. It is possible to “crank” or remove an inboard motor from the water, although it’s not always easy. Here are a few tips on how to do it:

1. First, make sure that you have all the necessary tools and supplies on hand, including a block and tackle (or similar lifting device), rope or straps, and someone to help you.

2. Next, disconnect the propeller shaft from the engine by loosening the retaining nut(s). You may also need to remove the propeller itself.

3. Once the propeller shaft is disconnected, secure it so that it doesn’t flop around and cause damage while you’re working. Many people use a length of rope or something similar for this purpose.

4. Now it’s time to start cranking the engine out of the water.

If you have a block and tackle, attach it to a solid point (like a cleat) on your boat and then hook the other end onto the engine mount bolts. Start cranking slowly and steadily until the engine is clear of the waterline.

Why Won T My Boat Motor Raise Or Lower?

If you’re having trouble getting your boat motor to raise or lower, there are a few things you can check. First, make sure that the kill switch is in the “on” position. Next, check the fuel level and make sure there’s enough gas in the tank.

If those two things are fine, then it’s possible that the problem is with the hydraulics. The hydraulic fluid level might be low, or there could be a leak in one of the hoses. You’ll need to take a look at the system and diagnose the problem before you can fix it.

How Do You Lift an Outboard Motor Without a Hoist?

There are a few ways that you can lift an outboard motor without a hoist. One way is to use a come-along or ratchet strap to pull the engine up. Another way is to use a block and tackle system.

And finally, you can also use a floor jack to lift the engine.

Using a come-along or ratchet strap:

1. Attach one end of the strap to the outboard motor and the other end to a solid object (like a tree or fence post).

2. Pull on the free end of the strap until the outboard motor is lifted off the ground.

3. Secure the outboard motor in place so it doesn’t fall back down.

Using a block and tackle:

1. Suspend the block and tackle from a strong overhead object (like a tree limb). Make sure that the object is very sturdy, as this system will be holding all of the weight of your outboard motor! If you’re not sure if your chosen object is sturdy enough, err on the side of caution and choose something else.

2. Attach one hook ofthe block and tackle onto your outboardmotor 3 . Start pulling onthe free endofthe rope untiltheoutboardmotoris liftedoffthe ground 4 . Securetheoutboardmotorin place soitdoesn’tfallbackdown Usinga floorjack 1 .

Place th efloor jackunderneathth eout board mo tor with th ejacksaddle restingon topof th em otor’spowerhead 2 . Pump th ehandleuntilth eout board m otorisraisedup offof th eg round 3 .

Simple and easy Raise manually your Outboard drive

Conclusion

If your inboard outboard motor is giving you trouble, don’t fret! With a little elbow grease, you can raise it manually. All you need is a screwdriver, an adjustable wrench, and a hammer.

First, remove the cotter pins from the lifting brackets. Then, use the screwdriver to loosen the bolts on the brackets. Next, adjust the height of the motor using the wrench.

Finally, tap the brackets with the hammer to lock them into place. Now your inboard outboard motor should be good as new!